Various owl experiments on a shelf in my studio (2000 - 2018)

https://www.smithsonianmag.com/arts-culture/a-brief-history-of-robot-birds-77235415/

open studio

Various owl experiments on a shelf in my studio (2000 - 2018)

https://www.smithsonianmag.com/arts-culture/a-brief-history-of-robot-birds-77235415/

Collage of photographic and computer generated graphics, 2018

Studying the landscape, sound structures, and insects real and imagined.

Landscape painting and analog electronic soundscape (detail of work in-progress). August 2018

I create the sound of a buzzy August insect using a 555 timer to drive a transistor astable multivibrator (to give timbre). Another slow astable multivibrator provides pulse input to a 555 timer in monostable configuration, that gives a pulse out to the base resistor of an astable multivibrator that sets the tempo. That's why the insect rattles for awhile and then stops (monostable 555 goes high - the rattle tempo is active low).

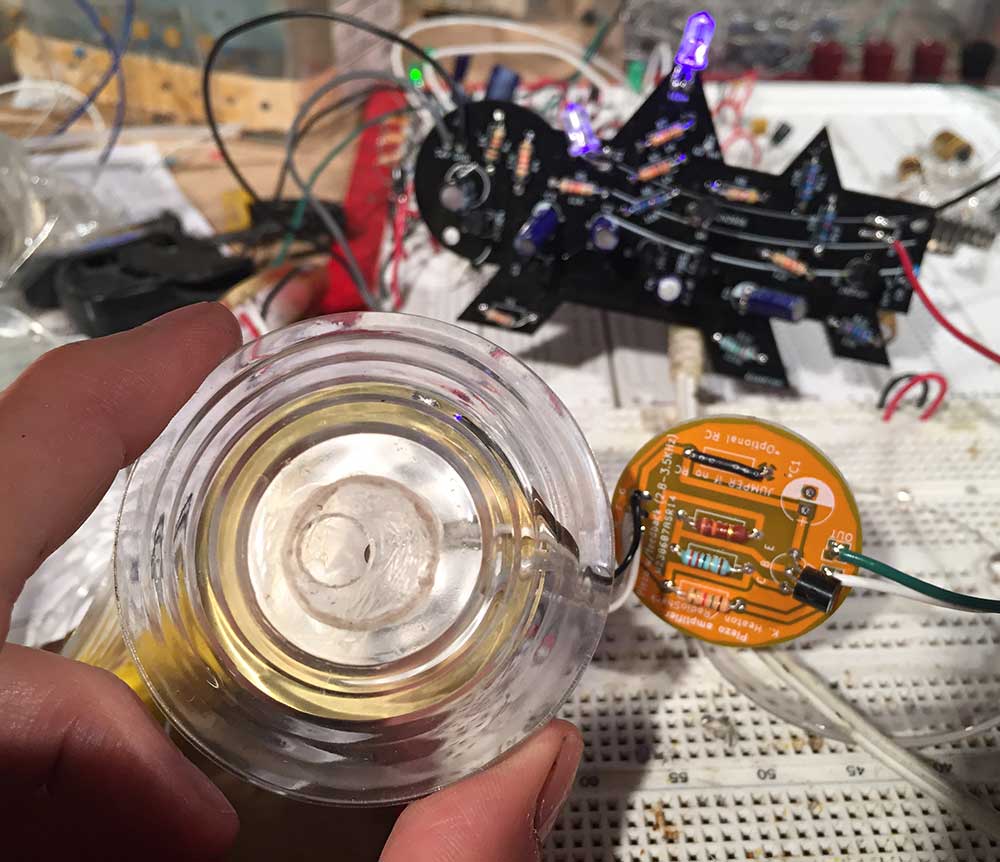

Here I am at my bench prototyping various analog electronic insects for my latest "electrolier" sculpture. The sounds are made using a combination of astable multivibrators (oscillators), some of which create the audio timber and others establish a chirp-like tempo. The speakers are custom piezo electric devices that I have physically modified to achieve different sound qualities, such as brighter versus muffled and close versus distant. Individuality is achieved by subtle variations in the electrical signal and the output device.

Using Blender to model and Pepakura to produce paper patterns for tree branches.

With the news blowing up about election interference, I can't resist reposting these paintings from last year: "Donald Trump (The Big Hack)" and "Vladimir Putin (The Operational Amplifier)." Politics, technology, gobbledygook, obfuscation, and sneakiness. Oil on canvas, 2017

Here's a prototype of a housing for a piezo speaker that I will actuate with analog electronic insect sounds. The shape of the housing and mechanical pressure on the piezo element will change the pitch as well as the volume. I made this housing by first laser cutting 1/4" acrylic and gluing the stacked rings to make a pyramidal-shaped buck — see images below. Note that there's a central hole all the way through the buck to aid the vacuum forming process. I’ve vacuum-formed .080” and .090" acrylic sheet over the buck (both work fine) and used a laser to cut the shapes out. My registration needs improvement, but you get the idea. The piezo element is mounted inside of the housing by a short length of plastic tube that I glued in place.

Below I show my process to cast the acrylic buck in plaster (using an alginate mold). I will use plaster, wood, or metal bucks in the future because acrylic deforms in the vacuum forming process. In either case, it is critical to use mold release.

Why am I doing this? Because when RadioShack went out of business, I could no longer buy the piezo speakers that I used for my insect sounds. I was forced to reverse engineer the part --which turned out to be a blessing because the sound of insects is heavily dependent upon the mechanics of speaker design (not just the electronics which drive the speaker). For a previous blog entry on this issue, link here or read about my project “Hacking Nature’s Musicians” on Hackaday.io